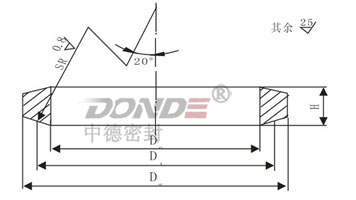

Description:ZD-G1840

lens ring joints' highest pressure used is 3000atm,they have been used

on pipe flanges in synthesizing line of ammonia and methand at high

pressure and high temperature,in high pressure polymerizing line of

polyethylene at 3000 atm.

Application:

ZD-G1840 is

suitable

to sealing of flanges at high temperature and pressure pipings It is

widely applied in petroleum processing,oil refining ,electricity

generated by firepower,textile and other light industries,pharmacy

,pipeline of nature gas,valve etc.

Standard:ANSI

B16.5-1973、JPI-75-15-70、GB 699、GB1220、JB755、HG20633-9

Note:The

material of the oval ring jont gasket must be 15~20HB

lower than the hardness of flange,and this kind of

gaskets is non-recyclable.

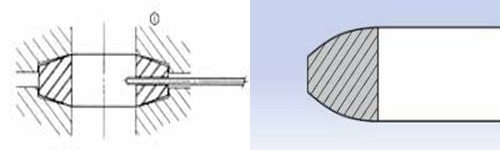

The cross section |

Available Material:

Material |

Maximum

Hardness |

Temperature( ℃ ) |

Abbreviations |

Brinell |

Rockwell“B”Grade |

Soft Iron |

90 |

56 |

-60~500 |

D |

Low Carbon Steel |

120 |

68 |

-40~540 |

S |

SS304 |

160 |

83 |

-250~540 |

304 |

SS304L |

160 |

83 |

-250~540 |

304L |

SS316 |

160 |

83 |

-200~815 |

316 |

SS316L |

160 |

83 |

-200~815 |

316L |

SS321 |

160 |

83 |

-200~870 |

321 |

SS347 |

160 |

83 |

-200~870 |

347 |

SS410 |

170 |

86 |

-40~850 |

410 |

5Cr-0.5Mo |

130 |

|

-29~650 |

|

Copper |

80 |

|

-100~315 |

|

Aluminum |

35 |

|

-200~425 |

|

Inconel 600 |

150 |

|

-100~1095 |

|

Incoloy 825 |

150 |

|

-100~1095 |

|

Monel 400 |

150 |

|

-100~760 |

|

Titanium |

215 |

|

-200~540 |

|

Nickel 200 - |

110 |

|

200~760 |

|

Hastelloy B2 |

230 |

|

-100~1095 |

|

Hastelloy C276 |

210 |

|

-100~1095 |

|

It is important to use proper packaging, handling and storage methods as

any bruise, gouge (dent, ding, etc.) or groove across the seal contact

area may prevent uniform coining and continuous intimate contact,

resulting in leakage in the area of damage. Any rough handling or

impact contact against hard surfaces or objects may cause damage to a

ring gasket that renders it unusable. Soft iron and carbon steel ring

gaskets must be kept dry to prevent rust and pitting.

The plating on these ring gaskets will provide some rust protection for

a short time but any extended storage in a damp atmosphere or wetness

may destroy the usefulness of these gaskets. Stainless steel ring joint

gaskets are more tolerant to wet and damp conditions.