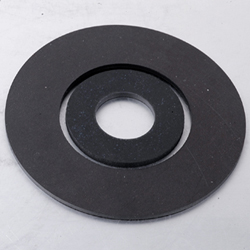

Description: ZD-G1600

is made by cutting PTFE stick, pipe and sheet into flat shape PTFE

gasket, v shape PTFE gasket or valve annulus PTFE gasket.PTFE gasket has

100% PTFE structure.It can bear the most bitter chemical medium, and

PTFE gasket has good anti-creeping performance.PTFE gasket is a

replacement of asbestos,and it is anti-creeping, anti-cold-flow,

anti-low-temerature.PTFE gasket has no pollution and is easy to install

and replace. under small pre-stress force,it can bear great internal

pressure even in a environment of changing pressure. It is the

best suit the condition with rough and fragile flange and

alternately-changing temperature.

Main Specification:

Pressure |

=<10MPa |

Temperature |

-180℃~260℃ |

PH Range |

0-14 |

Density |

2.1-2.3g/cm3 |

Size |

OD=<2000mm(special size can be made as

request) |

Modified

PTFE Gasket

Item No.:ZD-G1610

Description:As

we know,PTFE gasket is anti-creeping, anti-cold-flow, anti-low-temerature

and PTFE gasket has no pollution. If we add some more useful element

into the PTFE,the compression resistance and high temperature resistance

will be more perfect.For example,can add some fibreglass,graphite,bronze

to improve the character of pure PTFE gasket.We have PTFE gasket

reinforced with glass fibre,graphite PTFE gasket,reformative PTFE

gasket,PTFE bronze gasket,ect.

PTFE Graphite-filled Gasket:PTFE(teflon)

graphite-filled is synthetic material made of PTFE and grapphite.It has

perfect compressibility,recovery and sealing capability.Compared with

traditional PTFE,it improve the low-flow and creep properties.It

is more durable than normal PTFE gasket and extend the maintenance

period of flange.So PTFE(teflon) graphite is economical choice.

PTFE Glass-filled Gasket:It

is

It

Main Specification:

Pressure) |

=<16MPa |

Temperature |

-180℃-260℃ |

PH |

0-14 |

Density |

2.1-2.3g/cm3 |

Size |

OD=<2000mm(special size is made as request) |

Consulted Dimension:

No. |

Type |

Standard |

Type |

Standard |

1 |

RF 10A |

Φ53×Φ18×3t |

FF 10A |

Φ90×Φ18×3t |

2 |

RF 15A |

Φ58×Φ22×3t |

FF 15A |

Φ95×Φ22×3t |

3 |

RF 20A |

Φ63×Φ28×3t |

FF 20A |

Φ100×Φ28×3t |

4 |

RF 25A |

Φ74×Φ35×3t |

FF 25A |

Φ125×Φ35×3t |

5 |

RF 32A |

Φ84×Φ43×3t |

FF 32A |

Φ135×Φ43×3t |

6 |

RF 40A |

Φ89×Φ49×3t |

FF 40A |

Φ140×Φ49×3t |

7 |

RF 50A |

Φ104×Φ61×3t |

FF 50A |

Φ155×Φ61×3t |

8 |

RF 65A |

Φ124×Φ77×3t |

FF 65A |

Φ175×Φ77×3t |

9 |

RF 80A |

Φ134×Φ90×3t |

FF 80A |

Φ185×Φ90×3t |

10 |

RF 90A |

Φ144×Φ102×3t |

FF 90A |

Φ195×Φ102×3t |

11 |

RF 100A |

Φ159×Φ115×3t |

FF 100A |

Φ210×Φ115×3t |

12 |

RF 125A |

Φ190×Φ141×3t |

FF 125A |

Φ250×Φ141×3t |

13 |

RF 150A |

Φ220×Φ167×3t |

FF 150A |

Φ280×Φ167×3t |

14 |

RF 200A |

Φ270×Φ218×3t |

FF 175A |

Φ305×Φ192×3t |

15 |

RF 225A |

Φ290×Φ244×3t |

FF 200A |

Φ330×Φ218×3t |

16 |

RF 250A |

Φ333×Φ270×3t |

FF 250A |

Φ400×Φ270×3t |

17 |

RF 300A |

Φ378×Φ321×3t |

FF 300A |

Φ445×Φ321×3t |

18 |

RF 350A |

Φ423×Φ359×3t |

FF 350A |

Φ490×Φ359×3t |

19 |

RF 400A |

Φ486×Φ410×3t |

FF 400A |

Φ560×Φ410×3t |

20 |

RF 450A |

Φ541×Φ460×3t |

FF 450A |

Φ620×Φ460×3t |

21 |

RF 500A |

Φ596×Φ513×3t |

FF 500A |

Φ675×Φ513×3t |

22 |

RF 600A |

Φ700×Φ615×3t |

FF 550A |

Φ745×Φ564×3t |

|

|

|

|

Warning: Gasket materials should

never be recommended when both the

temperature and the pressure are at

the maximums listed. Properties and

applications shown are typical. No

application should be undertaken by

anyone without independent study and

evaluation for suitability. Never

use more than one gasket in one

flange joint, and never reuse a

gasket. Improper use or gasket

selection could cause property

damage and/or serious personal

injury. The data reported is a

compilation of field testing, field

service reports and/or in-house

testing. While the utmost care has

gone into publishing the information

contained herein, we assume no

responsibility for errors. The

information and specifications

contained in this website are

subject to change without notice.

This revision cancels and obsoletes

all previous editions.